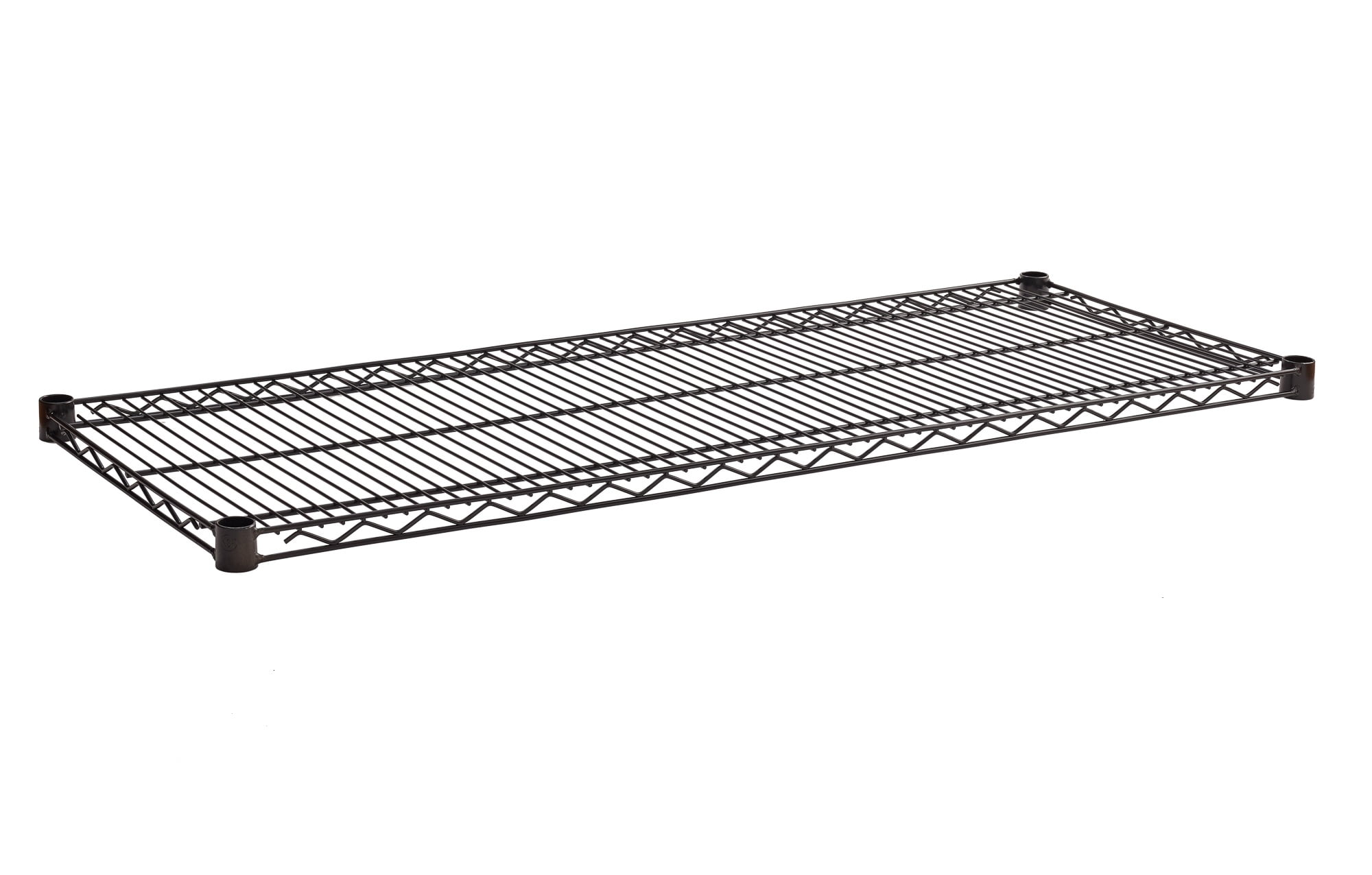

Solid Galvanized Shelving is a perfect shelving system to use where a Solid Shelf is desired.Stainless Steel Wire Shelving is the ultimate storage system for Laboratories, clean rooms, and hospital areas that have a rust or corrosion concern.Quantum's Stainless Steel Wire Shelving comes in both Wire and Solid Shelving styles.Our Epoxy Finish has a 15 year warranty against rust or corrosion. Green, Gray and Black Epoxy is a wonderful storage system that can be used in any wet or humid environment.Chrome Wire Shelving is by far the most popular wire shelving style we offer due to its simple assembly without tools! Quantum boasts the largest array of chrome shelf sizes and we have the largest amount of inventory in stock for quick shipping. The ever popular Chrome Wire Shelving System is perfect for any dry storage application.With storage capacities of 600-800 lb per shelf, wire shelving can help organize any storage area. Some wired units are fragile and will need support (a rigid bar placed at 45 degrees).Wire shelving has become one of the most popular storage systems available to consumers and Industrial users alike. Some wire shelves have support ends that go well with fasteners and can be hung at will. Not all shelves will be able to sit perfectly. The hook-like slots will hold the shelves in place. Now that the fasteners are installed, place the shelf and let it hang. If not, then start screwing the plastic anchor and then screw the metal fasteners for a solid hold. Some wire shelves will have built-in fasteners that will go directly to the holes you drilled. Wire shelves use plastic fasteners that resemble hooks. If you fail to do so, then use an anchor and screw it in.

#Wire shelves how to

– How to Properly Install Shelves into Concrete Wallsĭrill into the place where you’ve pencil marked the holes.

#Wire shelves crack

You don’t want to crack the surface with excessive to and fro of the rotating drill. If you have drywall, make sure you are gentle with it. Use a strong drill that can penetrate the concrete wall to a good length. It does require a bit of experience, if not, you are prone to damaging the wall. With all the markings in place, you will now have to perform the critical task, which I call it drilling. If you’ve noted the lines and holes on the wall, you are almost done lining up the shelf, now you have to move on to the main installation which desires a little effort. Get the leveler and line it up to mark the straight guidelines of the shelves. Once you know the locations, simply mark them with pencils. In this case, a stud finder (stud sensor) will help you pick the desired place. The wire shelves will have stud holes and to utilize them, you will have to locate the stud grooves. If you have drywall, then anchor screws and studs will work. Look for the wall type, if it is concrete then you might need competent screws and drills to make the perfect hole.

Once you’ve gathered all the items, then you must start by scouring the area where you will put up the shelves. Step 2: Know About The Installation Surface For a bracketless shelf, you will need pieces of equipment like

It won’t get attached automatically, rather need help from various contraptions and intricate measurements.

0 kommentar(er)

0 kommentar(er)